Importance Of Respirator Fit

Importance Of Respirator Fit

Respirator fit is important because it involves several major issues:

- Seal.

- Compatibility.

- Stability.

-

The Respirator's Seal

A good fit means the respirator will seal to your skin. A respirator can only work when air passes through the filter. Air will take the path of least resistance, so if the seal isn’t there, the air will go around rather than through the respirator – and therefore lessen the protection.

-

User Seal Check: An Essential Everyday Test

Employees wearing tight-fitting respiratory protection should perform a seal check each time they put on their respirator. A fit test ensures that the respirator is able to fit and provide a secure seal, but a user seal check ensures that it’s being worn right each time.

Users can either perform a positive-pressure or negative-pressure seal check:

- A positive-pressure check means blocking the exhalation valve on a half or full facepiece respirator or covering the respirator surface on a filtering facepiece, usually by using your hands, and trying to breathe out. If slight pressure builds up, that means air isn’t leaking around the edges of the respirator.

- A negative-pressure check involves blocking the intake valves on a half or full facepiece respirator or covering the respirator surface on a filtering facepiece, typically using your hands and trying to breathe in. If no air enters, the seal is tight.

See the product User Instructions for more details.

-

Compatibility with other PPE

Safety glasses, hearing protection, face shields, hard hats and coveralls can all vie with a respirator for real estate on a person’s face, head or body. For instance, if a half face respirator doesn’t fit well (especially if it’s too large), it can overlap with glasses. The more that happens, the more fogging can potentially occur on glasses, and the more likely it is that they’ll interfere with the respirator’s seal.

To catch these problems before they happen on the job any PPE that could interfere with the respirator’s seal to be worn during the fit test.

-

Respirator Stability

The better a respirator fits, the more stable it’s likely to be on the wearer’s face. Fit testing determines the respirator’s ability to retain its seal when the worker is in motion. That’s why test subjects are told to go through several exercises as part of testing. A respirator that shifts during movement may not be able to retain its seal.

3M Centre for Respiratory Protection

Overview of the Fit Testing Process

Tight-fitting respirators must seal to the wearer’s face in order to provide expected protection. This includes disposable respirators (also called “filtering facepieces”). Fit testing is required by Australian New Zealand Standard AS/NZS1715 before a user wears a respirator on the job, and should be assessed at least annually. In addition, fit tests should be performed:

- Whenever a different size, style, model or make of respirator is used.

- When any facial changes occur that could affect fit, such as significant weight fluctuation or dental work.

AS/NZS1715 doesn’t require fit test administrators to be certified, just to know how to conduct a test, recognize invalid tests, and properly clean and maintain equipment.

There are two kinds of tests: qualitative and quantitative.

-

Qualitative Fit Test (QLFT)

A qualitative fit test (QLFT) may only be used to fit-test:

- Negative-pressure, air-purifying respirators, as long as they’ll only be used in atmospheres where the hazard is at less than 10 times the permissible workplace exposure standard.

- Tight fitting facepieces used with powered and atmosphere-supplying respirators.

QLFT is pass/fail and relies on the user’s senses using one of he AS/NZS 1715 accepted test agents:

- Isoamyl acetate (banana smell); only for testing respirators with organic vapor cartridges.

- Saccharin (sweet taste); can test respirators with a particulate filter of any class.

- Bitrex® (bitter taste); can also test respirators with particulate filters of any class.

Each QLFT method uses seven exercises performed for 1 minute each:

- Normal breathing.

- Deep breathing.

- Moving head side to side.

- Moving head up and down.

- Bending over (or jogging in place if fit test unit doesn’t permit bending at the waist).

- Talking.

- Normal breathing again.

Based on OSHA fit testing protocols.

-

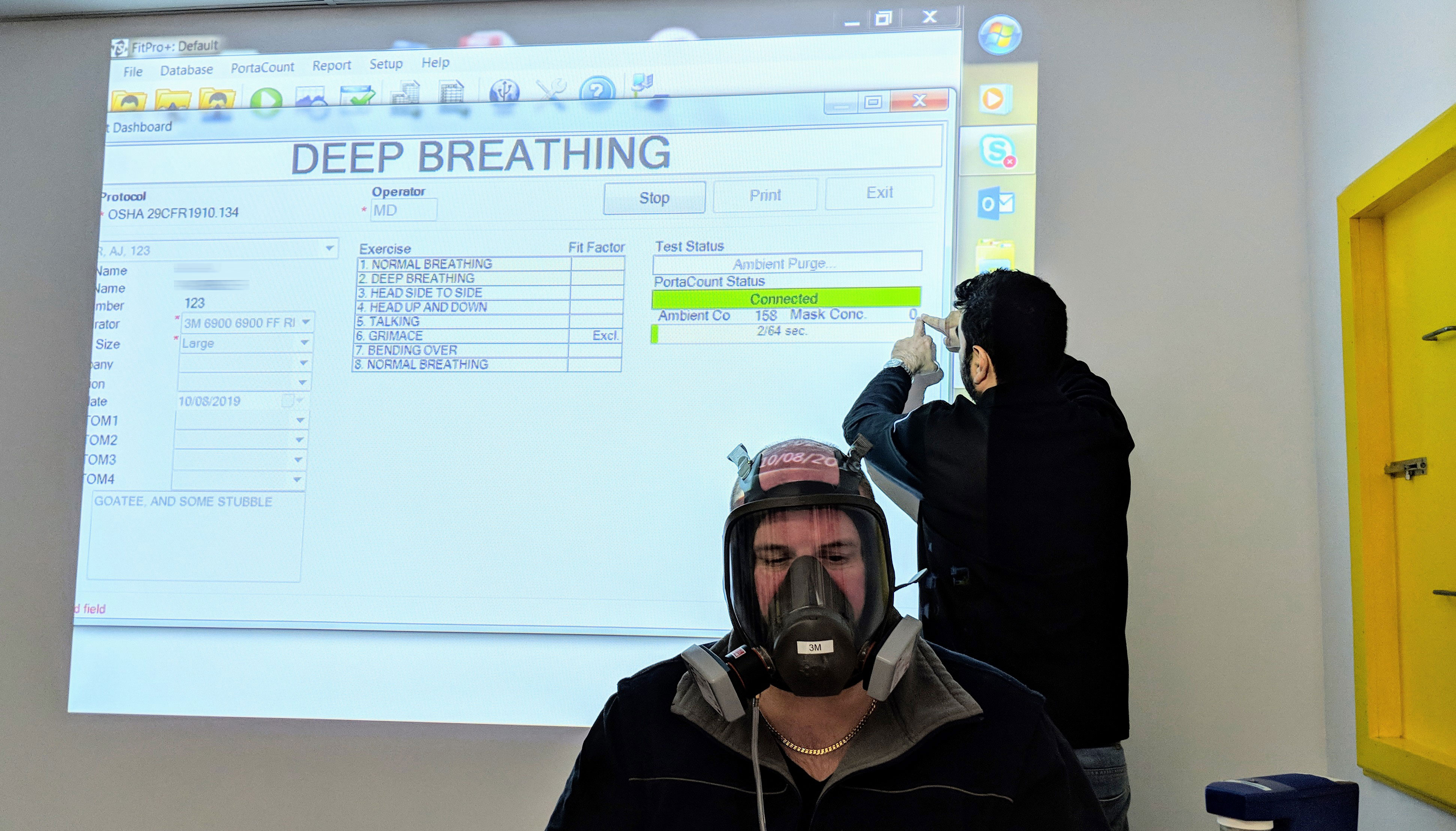

Quantitative Fit Test (QNFT)

A quantitative fit test (QNFT) can be used to fit-test any tight-fitting respirator. It involves using an instrument to measure leakage around the face seal and produces a numerical result called a “fit factor.” There are three accepted QNFT test protocols:

- Generated aerosoluses a non-hazardous aerosol such as corn oil generated in a test chamber.

- Condensation nuclei counter (CNC) uses ambient aerosol and doesn’t require a test chamber eg Portacount

A fit factor of at least 100 is required for half-mask respirators and a minimum fit factor of 500 or 1000 for a full facepiece negative-pressure respirator depending on the protection factor required in use.

Fit testing can be conducted in three main ways:

- By a competent individual e.g. an occupational health nurse or occupational hygienist. This option is ideal for individuals or businesses who do not have in-house expertise or resources and would like to include fit testing as part of their annual health monitoring. For more information on where to locate an occupational health nurse or trained individual please visit www.aioh.org.au.

- By purchasing a 3M Qualitative Fit Test Kit and participating in 3M Qualitative Fit Test training. This is ideal for organisations with in-house resource(s) and have a high turnover of staff, are in remote locations, have multiple shifts, contract workers, shut downs, seasonal requirements, urgent or short notice requirements*. Also ideal for upskilling staff and improving engagement in respiratory protection programs. Purchase your 3M Qualitative Fit Test Kit (FT-10) or 3M Qualitative Fit Test Kit (FT-30)

- Working with 3M on a comprehensive PPE programme including respiratory protection. 3M may include the provision of fit testing as part of the service offering. Click here for more information

- Fit tests must be performed before use of a tight-fitting respirator.

In addition, OSHA stipulates that fit testing of employees must occur at least annually; whenever a different size, style, model or make of respirator is used; and when any physical change occurs that could affect fit (such as, for example, significant weight fluctuation, dental work, or other facial changes).

- Disposable respirators need to be fit-tested.

Also known as filtering facepieces, these tight-fitting respirators must be fit-tested before mandatory use at a job site.

- Voluntarily used respirators don’t require fit testing.

If the employer provides respirators for voluntary use but they aren’t required, they don’t need to be fit-tested – but 3M still recommends it.

- Fit testers don’t require certification to perform fit tests.

However, the AS/NZS1715 standard does recommend that fit testers should know how to conduct a test, recognize invalid results, and properly clean and maintain equipment.

- There are two kinds of fit tests.

A qualitative fit test (QLFT) may only be used to fit-test certain negative-pressure, air-purifying respirators and positive-pressure, atmosphere-supplying respirators. It relies on the user’s ability to detect a particular taste, smell or irritant. A quantitative fit test (QNFT) can be used to fit-test any tight-fitting respirator. It involves using an instrument to measure leakage around the face seal and produces a numerical result called a “fit factor.”

- A respirator’s assigned protection factor (APF) is only valid if the respirator fits correctly.

The workplace level of respiratory protection that a respirator or class of respirators is expected to provide to employees when the employer implements a continuing, effective respiratory protection program as specified by AS/NZS 1715 Without fit testing, there’s no way of knowing if the respirator is actually able to provide its advertised level of protection for a specific worker.

- A good fit means the respirator will seal to your skin.

A respirator can only work when air passes through the filter. Air will take the path of least resistance, so if the seal to the face isn’t secure, the air will go around rather than through the respirator. Therefore, it is essential to ensure a proper fit when wearing tight-fitting respirators.

- Any PPE that could interfere with the respirator’s seal must be worn during the fit test.

Respiratory protection is often worn simultaneously with other personal protective equipment (PPE). Safety glasses, hearing protection, face shields, hard hats and coveralls can all vie with a respirator for real estate on a person’s face, head or body, and could interfere with the respirator’s seal. Fit testing should ensure that equipment is compatible and doesn’t reduce the effectiveness of the respirator due to a compromised face seal.

- Tight-fitting respirators cannot be properly work with facial hair.

Beards, mustaches, or even stubble interfere with the seal of a tight-fitting respirator. That’s why AS/NZS 1715 requires that employees be clean-shaven the day of the fit test and prohibits any facial hair in areas where the respirator comes into contact with the face.

- A respirator that shifts during movement may not retain its seal.

That’s why fit testing involves several exercises, such as head turning and speaking. This determines the respirator’s ability to retain its seal when the worker is in motion.

Fit Testing Resources

As pioneers in the field of respiratory protection, 3M not only invented the first AS/NZS 1716 compliant filtering facepiece disposable respirator, they helped develop qualitative fit testing protocol used today. They have a deep bench of experienced and passionate experts eager to spread knowledge about and increase understanding of this crucial part of respiratory protection.

-

3M P2 N95 9322A+ Respirator Aura Flat Fold Mask with valve- PK 10

Regular Price: $74.95

NOW: $69.95

-

3M P2/P3 Particulate Rectangular White Filter (6035)

Regular Price: $24.95

NOW: $19.95

-

3M A1B1E1K1 Multi Gas Cartridge Filter (6059)-Pk 2

Regular Price: $44.95

NOW: $39.95

-

3M P2 Aura Medical & Industrial Respirator (9320A+) - PK-20

Regular Price: $69.95

NOW: $64.95

-

-

-

-

3M Sensitivity Solution - Bitter (Bitrex) (FT-31)

Regular Price: $49.95

NOW: $44.95

-

3M Versaflo Powered Air Kit with Versaflo Helmet (TRM-307C)

Regular Price: $2,959.95

NOW: $2,809.95

-

3M Fit Test Solution - Bitter (Bitrex) (FT-32)

Regular Price: $49.95

NOW: $44.95

-

-

3M Versaflo M-407 Helmet with Flame Resistant Shroud PAPR

Regular Price: $1,324.95

NOW: $1,254.95