Eye Protection

The portfolio of 3M™ Eye Protection products promises quality eyewear that provides an optimal balance of comfort, protection and design. 3M™’s Engineers have worked hard to ensure that the level of comfort and style matches the standard of protection offered. The 3M™ portfolio offers the highest level of optical class. A broad range of eyewear products include durable anti-scratch and convenient anti-fog coatings.

About the range

Eye Protection products are used in many industries to protect against fl ying particles, liquids, chemicals, molten metals, radiated head and glare. The 3M™ range of safety spectacles and goggles off er the user protection from eye hazards including medium impact flying fragments. Our 3M™ safety spectacles and goggles can be used in conjunction with other Personal Protective Equipment products to give you added protection in diff erent situations. The 3M™ eye protection portfolio off ers an unrivalled range of products for companies looking for comfortable and high-quality solutions to meet a variety of industrial applications.

Style

Style is a critical factor when it comes to raising the acceptance of the user to wear personal protective equipment (PPE). 3M™’s range of eyewear gives you a variety of modern and stylish products from which to choose.

Protection

The 3M™ range of eyewear off ers high quality optics. Most of the 3M™ glasses and goggles off er reliable UV protection and

all are tested and comply with AS/NZS1337.1

Comfort

Many of our products come with adjustable features and soft materials in points of contact in order to improve fi t and comfort to accommodate diff erent face sizes and shapes.

Compatibility

Eye protection often needs to be worn in conjunction with other protective equipment and it is essential that comfort and fit with other PPE is maintained. Most of the eyewear and goggle ranges can be used in combination with respiratory and hearing protection by 3M™. Compatibility with other PPE will be subject to a number of variable factors which requires the employer and end user to determine an appropriate selection depending on individual needs.

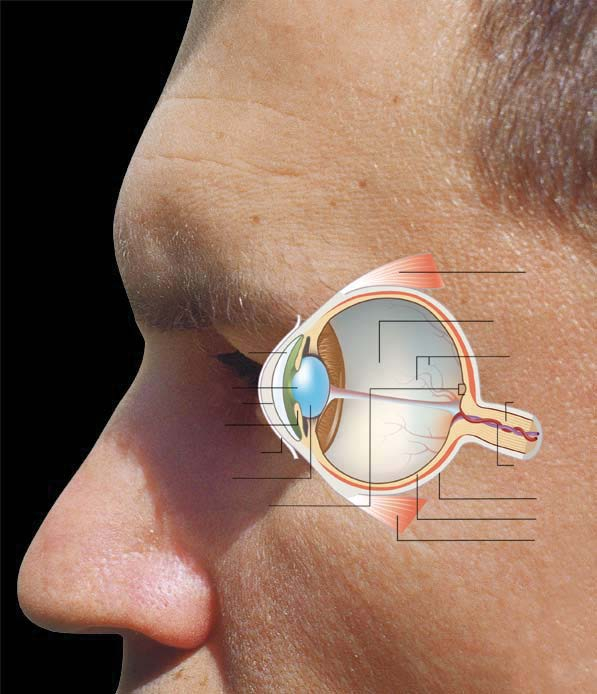

Human eye

The Cornea in direct contact with an external environment, plays an essential part in the transmission of light rays. There are more nerve endings in the cornea than anywhere else in the body.

The Pupil (light controller), situated in the middle of the iris, works like the diaphragm of a camera. Its diameter changes in

accordance with the light levels.

The Lens allows focusing (near vision, far vision) thanks to a control muscle. With age this muscle loses power and impacts

near vision (presbyopia). The lens can lose its transparency due to exposure to IR (infrared light) and UV (ultraviolet light),

resulting in loss of vision (cataract).

The Retina is where all light beams converge; it transmits all information through the optic nerve to the brain in order to create your vision. Burned retina cells are lost forever which causes irreversible loss of vision.

Industrial hazards for the eyes:

- Mechanical hazards: dust, shock, solid particles.

- Thermal hazards: hot liquid, molten splash, flames.

- Chemical or Biological hazards: splashes of acids, solvents, alkalis, infected blood.

- Radiation hazards: ultraviolet, infrared, visible light, laser.

- Electrical hazards: direct contact, short-circuit electric arc.

Protection all the way

Eyewear injuries happen when you least expect them. Be prepared.

We believe that health and safety are the priorities in any working environment, and that greater comfort and modern styles improve worker compliance with regulatory requirements for protective eyewear.

Therefore, we take care in adding comfort features where they are needed most, such as heavy contact areas like nose

bridges and temple tips. The materials we choose to provide better comfort are designed to be durable to last and soft to

the touch. We are also continually working on new coatings, new materials and new designs to bring the latest technology,

innovation and fashion into our protective eyewear line.

What contributes to eye injuries at work?

- Not wearing eye protection. Nearly three out of every five workers injured are not wearing eye protection at the time of the accident.

- Wearing the wrong kind of eye protection for the job. 40% of the injured workers were wearing some form of eye protection when the accident occurred. However, these workers were most likely to be wearing protective eyeglasses with no side shields.

What causes eye injuries?

-

Flying particles. Almost 70% of accidents resulted from flying or falling objects or sparks striking the eye. Injured

workers estimated that nearly three-fi fths of the objects were smaller than a pinhead. Contact with chemicals caused

one-fifth of the injuries.

Where do accidents occur most often?

- Craftwork. Potential eye hazards can be found in nearly every industry, more than 40% of injuries occurred among craft workers, like mechanics, repairers, carpenters and plumbers.

- Industrial equipment operation. Over a third of the injured workers were operators, such as assemblers, sanders, and grinding machine operators. Almost half of these injured workers were employed in manufacturing.

How can eye injuries be prevented?

- Always wear eff ective eye protection. AS/NZ standards require that employers provide workers with suitable eye protection. To be eff ective, the eyewear must be of the appropriate type for the hazard encountered and properly fitted.

- Better training and education. Workers injured while not wearing protective eyewear most often said they believed it was not required by the situation. Even though the vast majority of employers furnished eye protection at no cost to employees, about 40% of the workers received no information on where and what kind of eyewear should be used.

- Maintenance. Eye protection devices must be properly maintained. Scratched and dirty devices reduce vision, cause glare and may contribute to accidents. Scratched or damaged eyewear should be replaced immediately.

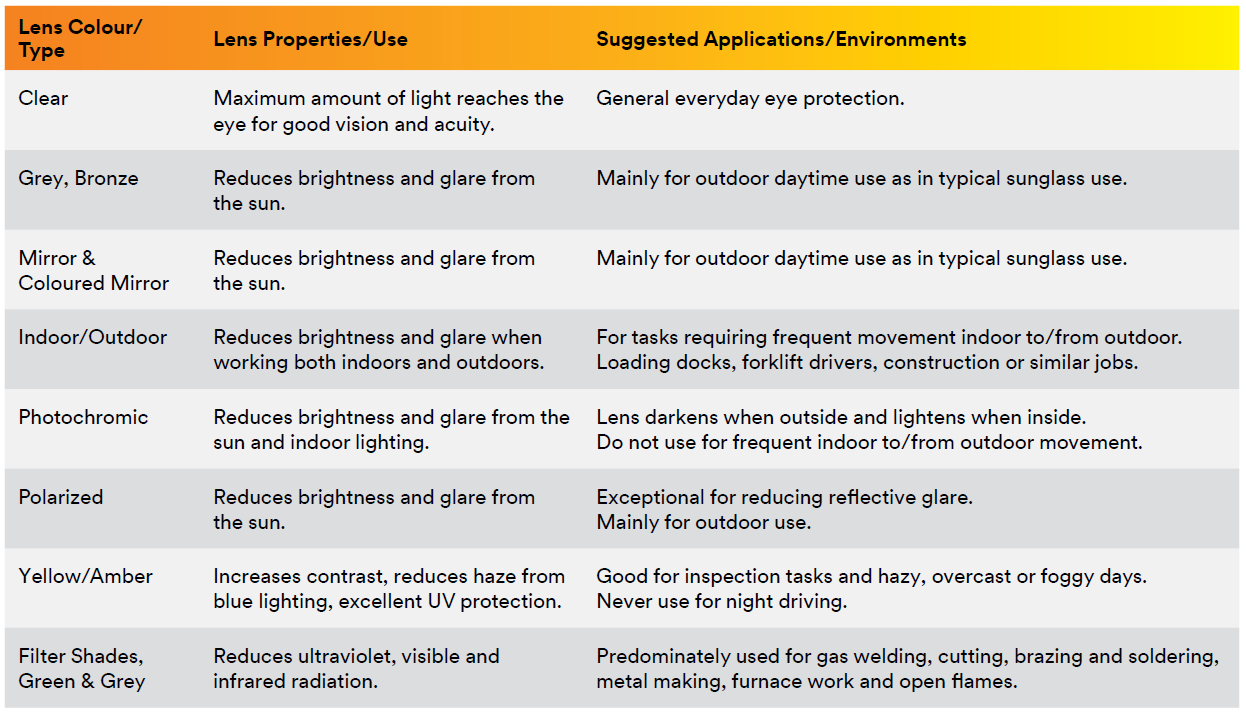

How to pick the right tinted safety glasses for your job

Safety glasses come in numerous shapes and styles, but do you know how to choose the right tinted safety glasses for your job?

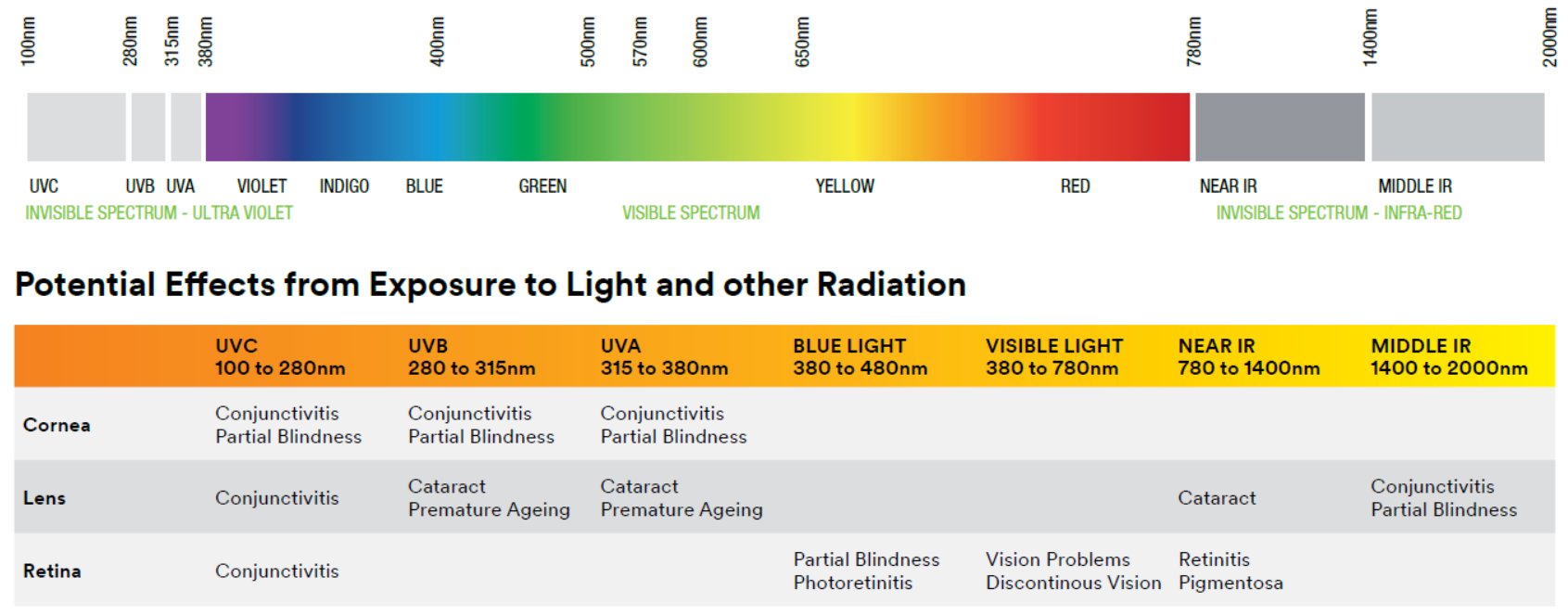

Safety glasses are available in many diff erent tints that serve any different purposes, depending on the job at hand and your environment. Tinted safety glasses can help reduce glare, reflect bright light, absorb harmful light, including UV and infrared (IR), and even increase contrast in your field of vision. We’re discussing the reasons why selecting the right lens for your specific application is so important and sharing what you need to know about our top four most popular lens tints.

Why does choosing the right lens matter?

Safety

The top reason why lens tint matters comes down to safety. When you’re wearing the right colour of tinted lenses, not only will this help protect your eyes from the hazards of the job at hand, your eyes can feel less fatigued from strain that can result from different working conditions. This can result in fewer instances of workers removing eyewear from their face due to discomfort, thereby keeping them safer. It’s also important to look for eyewear that meets AS/NZS 1337.1:2010, which means it has passed impact testing and other safety requirements that can help protect your eyes.

Health

Health

The right eyewear can help reduce light sensitivities, eye strain and headaches for wearers. Polycarbonate lenses contain UVA and UVB coatings, which help protect eyes from light conditions that can damage them and increase a wearer’s risk of developing eye disease, including cataracts. Different people have diff erent needs, and choosing the right lens tints can be benefi cial to a worker’s health.

Productivity

Certain lens tints provide contrast and can help workers see fine details better and more easily. This can help workers complete certain tasks more accurately and more quickly.

Comfort

This is one of the most important considerations when choosing a lens tint - and personal protective equipment (PPE) in general! When PPE is comfortable, workers are more likely to wear it and keep it on. This is why 3M produces so many different styles of safety eyewear and encourages sampling different pairs of safety glasses to see what will work for a worker’s individual face size and shape. To help objectively measure comfort and fi t, we specially developed the 3M™ Eyewear Fit Testing System to help measure gaps and fit around the eyes to promote optimal protection and comfort.

3M™ Protective Eyewear Lens Tints

Clear

It likely isn’t a surprise that clear safety glasses are the most popular choice of safety glasses. Luminance transmittance is

the highest with clear safety glasses, at 93%. This means that a clear lens allows for the maximum amount of light to pass

through the lens, which is benefi cial for tasks requiring well-lit environments. Safety eyewear lenses made with polycarbonate

will naturally absorb approximately 99% of UVA and UVB light, which provides additional protection to the user. All 3M polycarbonate lenses have been tested to the newest AS/NZS 1337.1:2010 to ensure compliance and safety. Safety glasses with clear lenses are best for everyday use and are appropriate for a wide variety of applications and uses.

Polycarbonate lens selection guide

This Polycarbonate Lens Selection Guide will help you understand the need for diff erent colour lenses and lens types for industrial applications. It will also help you determine what type of lens is best for your application and environment. There are many lens options other than Clear, Grey and Mirror. When choosing a lens, the basic “rule of thumb” is to consider colour opposites.

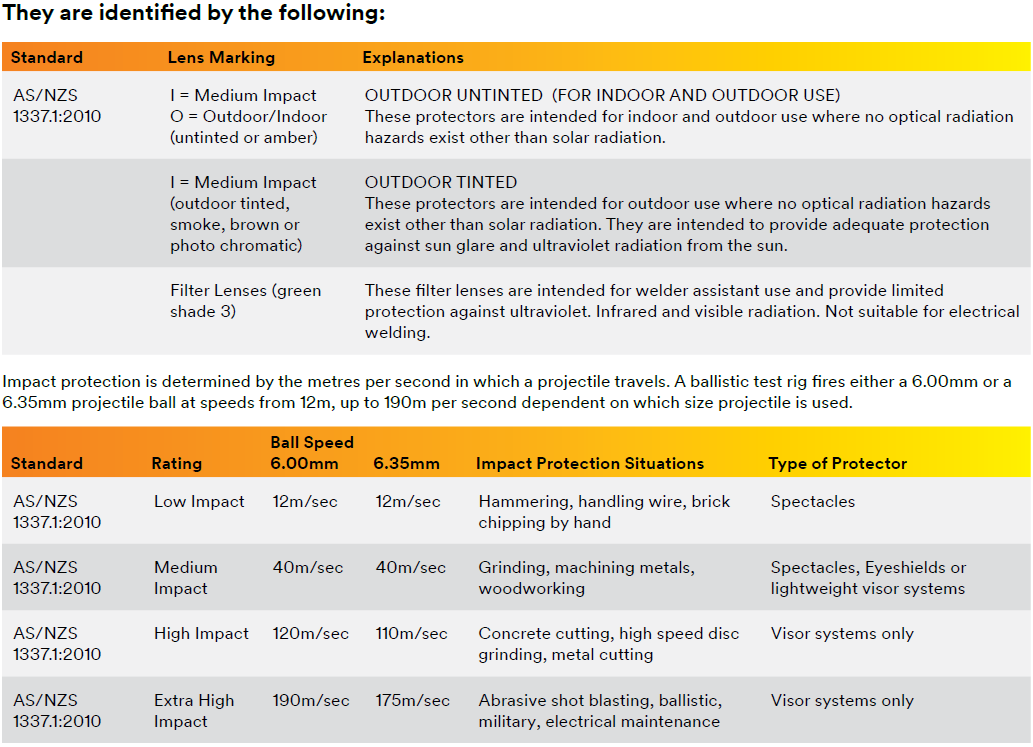

Lens markings

Markings on eye protectors are a requirement for certification. It assists users in identifying their intended use.

They are identified by the following:

Australian/New Zealand Standards AS/NZS 1336:2014 is an excellent reference document and provides assistance.

Medium impact safety spectacles provide protection from medium energy flying particles. For more information on tinted lenses and compliance testing to AS/NZS 1067 (sunglass standard) contact 3M.

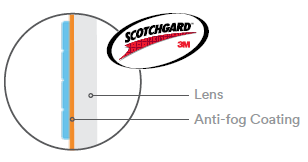

3M™ Scotchgard™ Anti-fog Coating Technology. Helps workers see clearly, longer.

- Scotchgard™ Anti-fog Coating lasts longer than traditional anti-fog coatings,* helping to increase eyewear performance in wet and steamy environments

- Workers may enjoy reliable, clearer sight longer, because the coating with its active ingredient, is bonded to the lens

- The coating retains its eff ectiveness for at least 25 washings, allowing workers to wear their eyewear longer*

- Workers can feel confi dent wearing Scotchgard™ anti-fog coated eyewear because it meets the requirements of AS/NZS 1337.1:2010

* Based on 3M internal testing per EN168 test method when compared with traditional anti-fog coatings.

Uncoated

When microscopic water droplets land on the lenses, they bead up and form condensation and fog, obscuring your vision.

Scotchgard™ coated

Scotchgard™ Anti-fog Coating produces a reduced-contact angle, flattening the water beads into a thin, transparent fi lm of water that allows light to pass through.

3M™ Pressure Diff usion Temple (PDT) Technology helps provide a secure, snug fit, while not compromising comfort.