Differential Permeation. Applied to returning you home safely.

Science has the power to change the world, solve the toughest problems and shape the future. But science is just science, until you apply it to something. Make it do something, change something. No one knows this better than 3M. The average person uses 3M science many times a day and doesn’t even know it. But it is everywhere, supporting 46 separate technology platforms and continuously driving our innovations. No other company uses science like we do. That’s 3M Science. Applied to life.™

At 3M we have a select and high quality range of Coveralls, which provide protection against many hazards. The 3M range of Protective Apparel offers a variety of features, from the use of fabrics with specialist treatments for enhanced wear and added protection, to breathable back panels for increased comfort. Our experts can work closely with you, to help you identify hazards and best protect your workers against them.

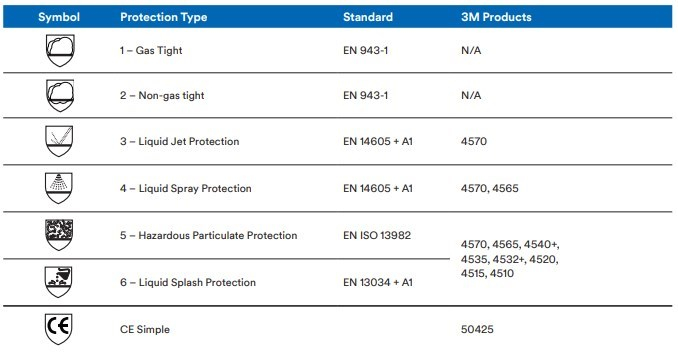

Standards

There are many tests and standards that apply to protective coveralls and selection can be a daunting task. The following section outlines the different options available to help you select the right product for your employees.

Protection Types

Depending on the materials and construction protective coveralls can be designed for either hazardous applications or nonhazardous applications. Products for hazardous applications can be tested and certified to any of six different “Type” standards providing guidance on suitability of use:

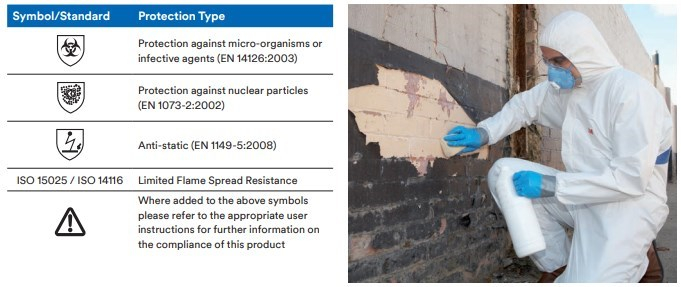

Additional Standards

Some 3M™ Protective Coveralls and their materials are approved to additional standards for specialist applications.

Materials

The following is a guide that off ers a brief description and comparison of the materials used in 3M’s protective coverall range. Base materials can be treated, for instance, with an anti-static treatment, to enhance the total protection offered.

Non-woven Polypropylene Offers comfortable light-duty protection against nonhazardous liquids and dust.

Spunbond-Meltblown Polypropylene (SMS) ‘SMS’ can be layered diff erently to adjust the protective and physical properties of the material. Standard SMS-material is very breathable and off ers a good barrier against dusts and limited liquid splashes. If treated, as 3M’s Protective Coverall 4532+, an enhanced level of splash protection can be achieved.

Microporous Laminates ‘Microporous laminates’ off er a higher level of liquid splash protection, while the micropores allow for some breathability.

Non-microporous Laminates ‘Non-microporous laminates’ can off er an even higher level of liquid protection. Adding multiple layers of the laminate can also increase robustness and chemical hold.

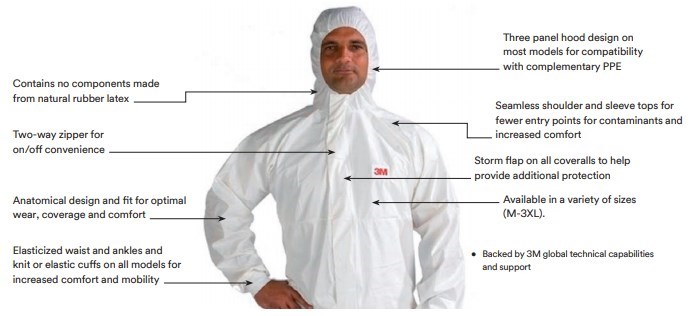

Design Features

3M™ Protective Coveralls can off er a variety of features depending on your needs. The illustration below highlights some of the features available:

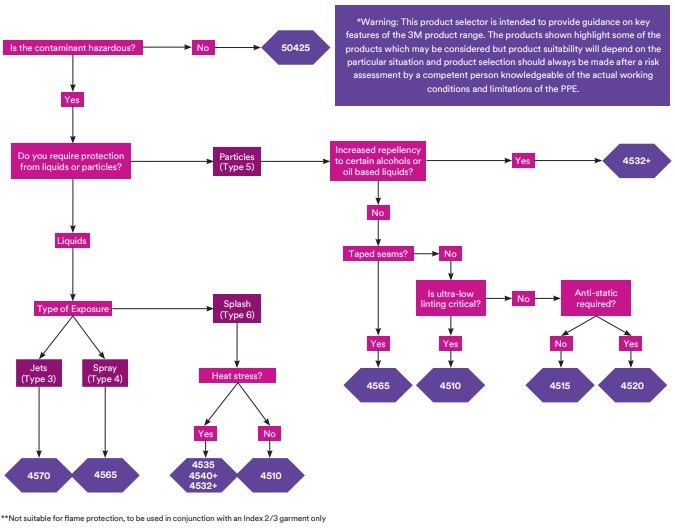

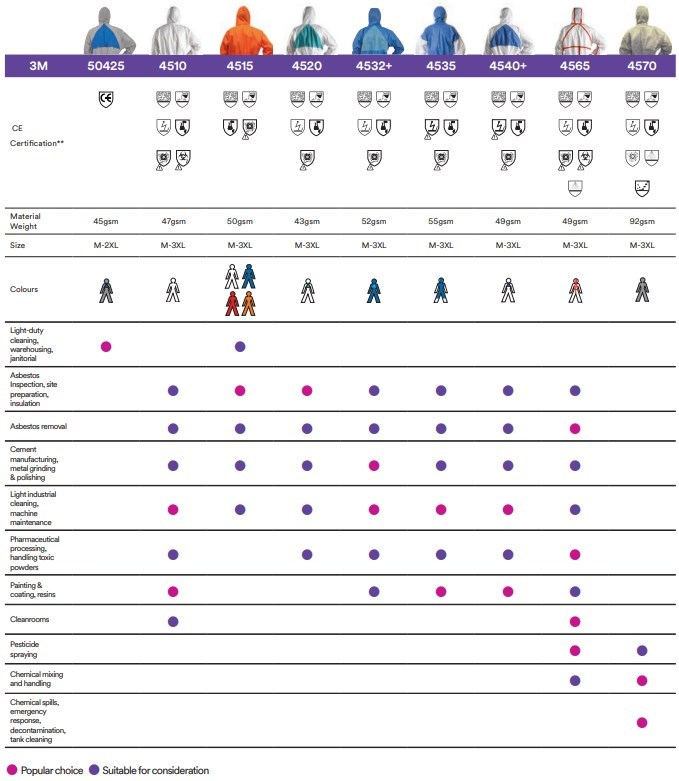

Product selector diagram

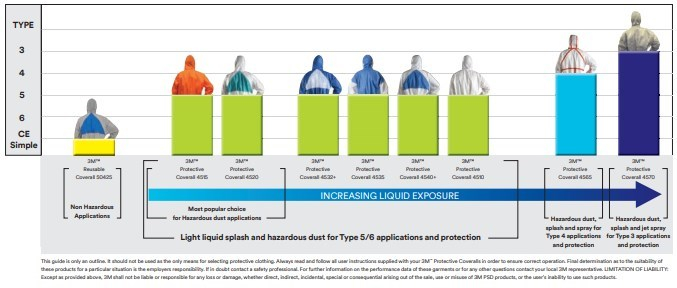

3M™ Protective Coveralls Protection Types

Product selector table

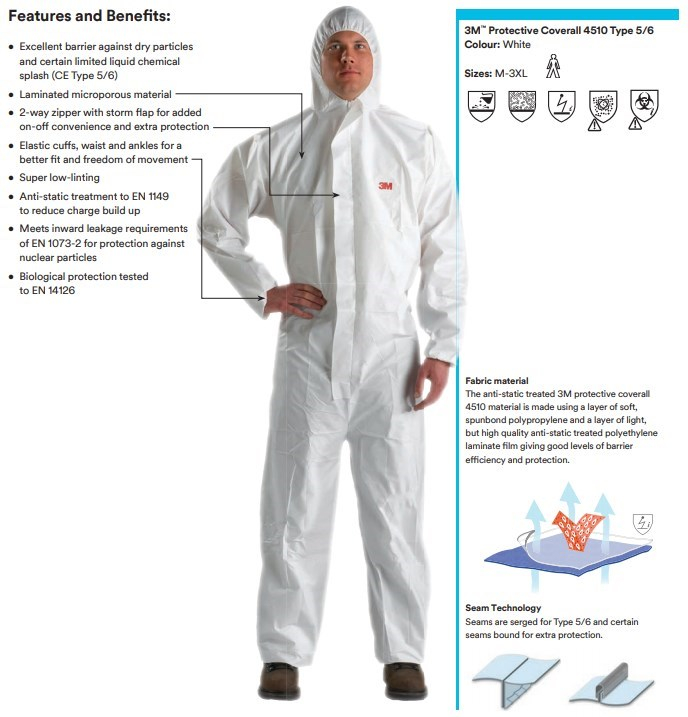

3M™ Protective Coverall 4510

The 3M™ Protective Coverall 4510 is an economic solution which off ers quality and protection from limited chemical splashes such as those from paint spraying and is certifi ed as CE Type 5/6 protection standard. The material is microporous, allowing air and moisture to escape from within the suit, while helping to protect from the hazard on the outside.

Typical Applications

Popular Choice

- Light industrial cleaning

- Machine maintenance

- Paint spraying & powder coating

- Coating & resin applications

- Crime scene investigation

Suitable for Consideration

- Asbestos inspection and removal

- Site preparation, insulation.

- Cement manufacturing

- Grinding & polishing

- Pharmaceutical processing & handling toxic powders

- Cleanrooms

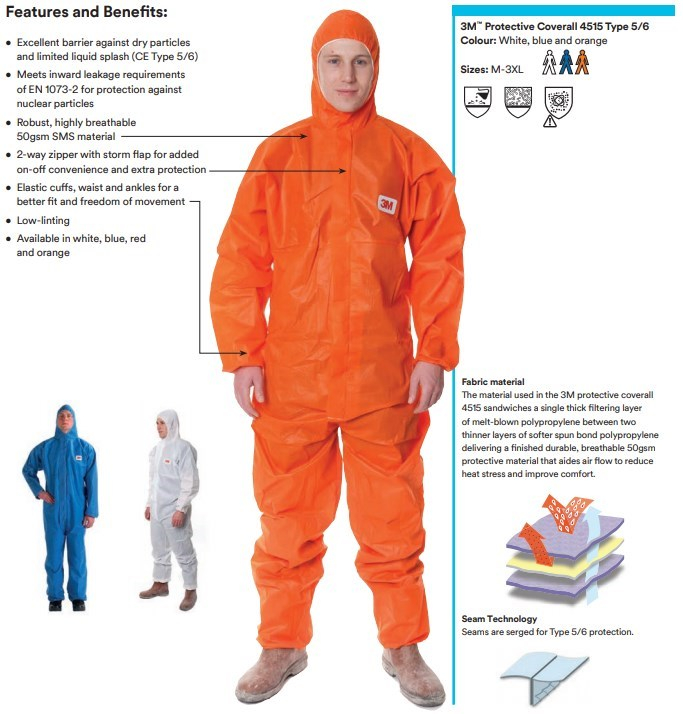

3M™ Protective Coverall 4515

Low cost hazardous dust protection

The 3M™ Protective Coverall 4515 is an economic solution to protect from hazardous dusts such as asbestos fi bres exposed to during site inspection. While protecting on the outside, the breathable material allows air to escape from the inside to reduce heat build-up and discomfort. Available in white, blue, red and orange, the range is certifi ed as CE Type 5/6 for both hazardous dusts and liquid splashes.

Typical Applications

Popular Choice

- Asbestos inspection

- Site preparation, insulation

- Construction

Suitable for Consideration

- Cement manufacturing

- Grinding & polishing

- Light industrial cleaning

- Machine maintenance

4515

-

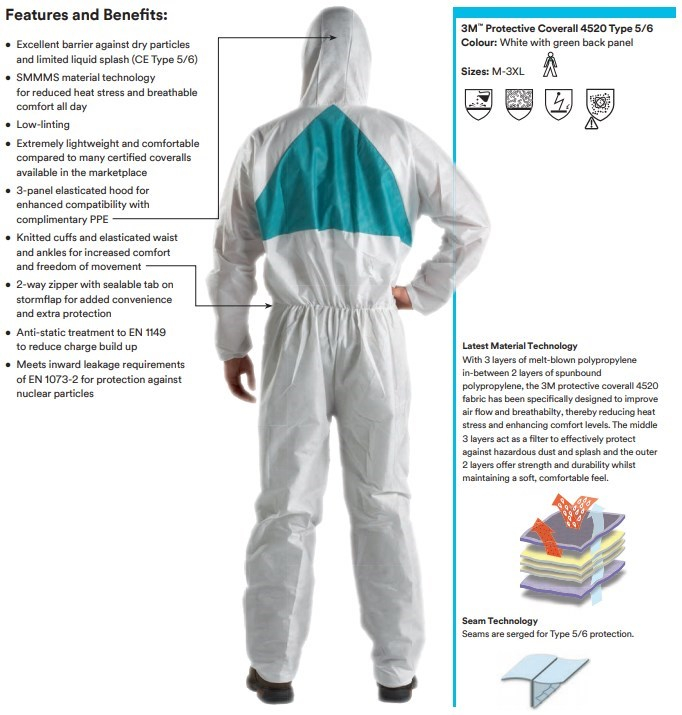

3M™ Protective Coverall 4520

Made using the latest lightweight, breathable material technology 3M presents the 3M™ Protective Coverall 4520, a Type 5/6 protective garment.

Typical Applications

Popular Choice

- Asbestos inspection

- Site preparation, insulation

- Pharmaceutical processing and handling toxic powders

Suitable for Consideration

- Asbestos removal

- Cement manufacturing

- Grinding & polishing

- Light industrial cleaning

- Machine maintenance

- Construction work

- Light paint spraying/powder coating

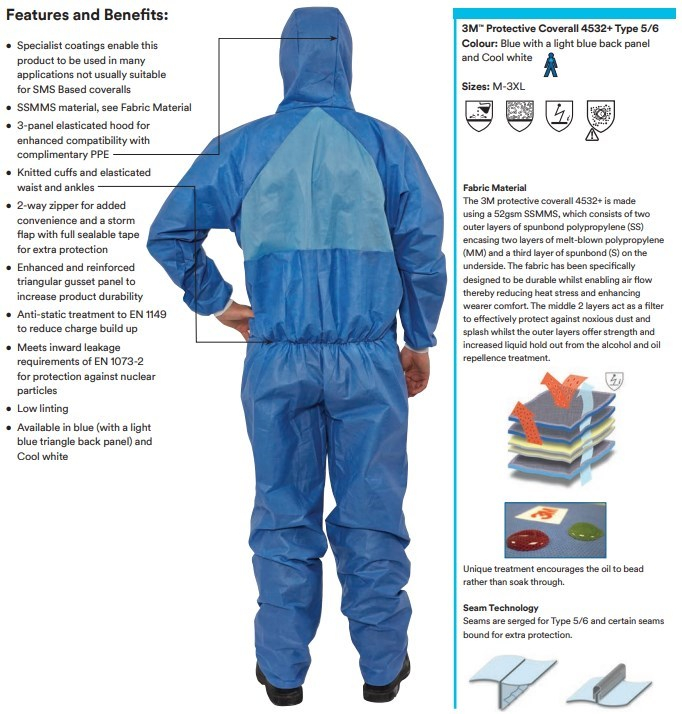

3M™ Protective Coverall 4532+

The 3M™ Protective Coverall 4532+ range is made from a highly breathable and lightweight 5 layered SSMMS material, providing the wearer with CE Type 5/6 protection with specialist treatments providing anti-static protection and an enhanced liquid repellency.

Typical Applications

Popular Choice

- Metal grinding and polishing

- Oil/greasy environments

- Painting and coating

- Cement manufacturing

Suitable for Consideration

- Light industrial cleaning

- Machine maintenance

- Pharmaceutical processing

- Handling toxic powders

- Resin applications

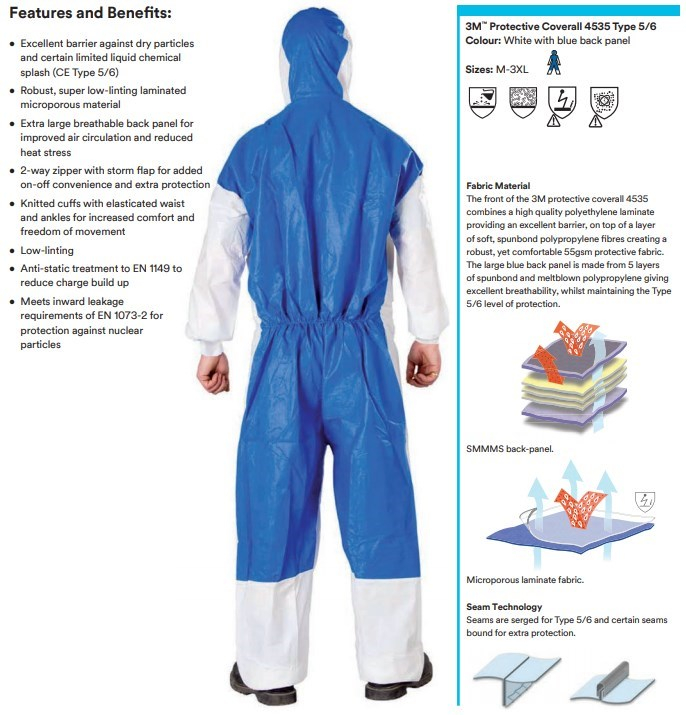

3M™ Protective Coverall 4535

If you’re looking for a balance of protection, durability and additional comfort, look no further than the 3M™ Protective Coverall 4535. Certified as CE Type 5/6 protection, it utilises a dual material design with added comfort features to optimise wearer acceptance.

Typical Applications

Popular Choice

- Coating & resin applications

- Light industrial cleaning

- Machine maintenance

- Paint spraying & powder coating

- Forensics

Suitable for Consideration

- Asbestos inspection and removal

- Site preparation, insulation

- Cement manufacturing

- Grinding & polishing

- Pharmaceutical processing and handling toxic powders

3M™ Protective Coverall 4540+

With premium dual material technology and offering CE Type 5/6 protection, the 3M™ Protective Coverall 4540+ is ideal for applications where both high levels of protective performance and comfort are desired.

Typical Applications

Popular Choice

- Paint spraying & powder coating

- Coating & resin applications

- Light industrial cleaning

- Machine maintenance

Suitable for Consideration

- Asbestos inspection and removal

- Site preparation, insulation

- Cement manufacturing

- Grinding & polishing

- Pharmaceutical processing and handling toxic powders

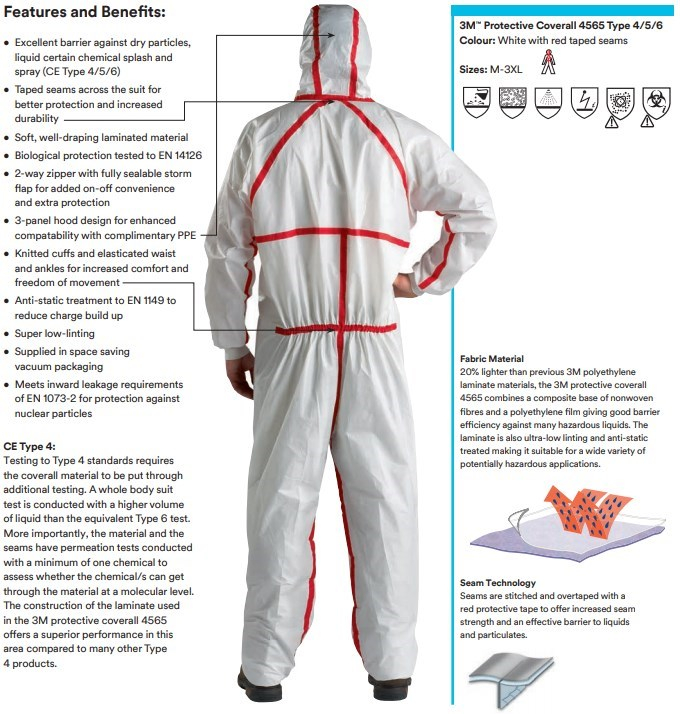

3M™ Protective Coverall 4565

Offering CE Type 4/5/6 protection, the 3M™ Protective Coverall 4565 has an impressive level of liquid barrier protection whilst maintaining its unique soft feel and wellfi tting drape. With tape applied over the seams a greater level of total protection and seam durability is off ered versus Type 5/6 products.

Typical Applications

Popular Choice

- Asbestos removal

- Pharmaceutical processing

- Handling toxic powders

- Cleanrooms

- Pesticide Spraying

Suitable for Consideration

- Asbestos inspection

- Site preparation, insulation

- Cement manufacturing

- Grinding & polishing

- Industrial cleaning and maintenance

- Painting & coating, resins

3M™ Protective Coverall 4570

The 3M™ Protective Coverall 4570 is a high performance chemical protective suit, certifi ed to Type 3/4/5/6 levels of protection, making it suitable to protect against a range of chemical jets and sprays. With additional design features including an enlarged zip and fi nger loops, a double-closing storm fl ap system and chin fl ap, convenience of use can be off ered without compromising the high level of protection given.

Typical Applications

Popular Choice

- Chemical mixing and handling

- Chemical/oil spills and clean up

- Metal Refi ning • Metal Etching

- Hazardous waste remediation

- Decontamination/Site Decommissioning

- Tank cleaning

- Infective agents/Biological Hazards

- Handling Toxic Powders

Suitable for Consideration

- Light industrial cleaning

- Machine maintenance

- Pharmaceutical processing

- Handling toxic powders

- Resin applications

4570

-

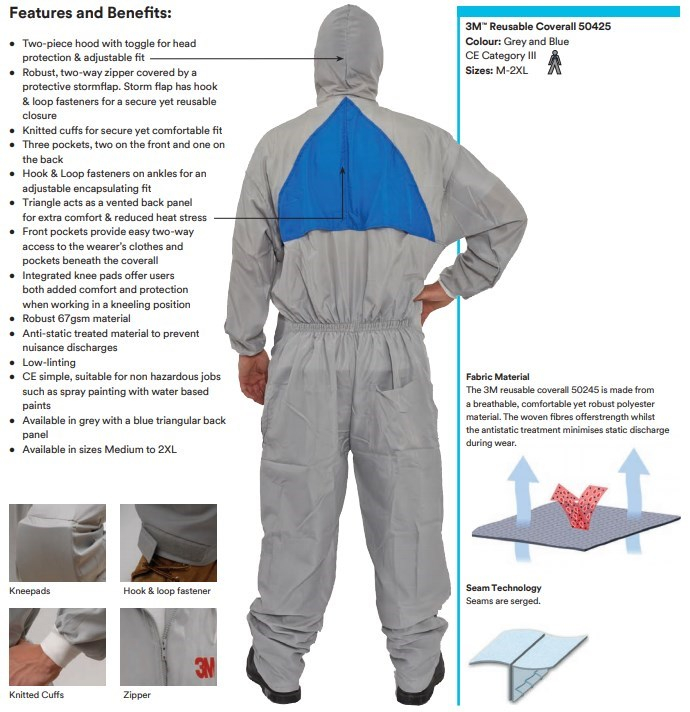

3M™ Reusable Coverall 50425

The 3M™ Reusable Coverall 50425 provides user and garment protection in a wide variety of environments and situations. Extremely comfortable, it is made from a lightweight, breathable polyester. The coverall has wide leg openings with adjustable hook and loop straps around the ankle, making it easy to put on and remove, even when wearing boots.

Typical Applications

- Paint spraying (water based paint, non-hazardous)

- Dusting, sanding and polishing

- General body and mechanical work and preparation

- Cleaning and area maintenance