Are you protected?

Are you protected?

Respirators are a simple and effective solution that can help to protect against what can be a potentially deadly issue when it comes to occupational health and safety.

Our natural protections against respiratory illnesses include a lung-clearing mechanism using small hairs called cilia that line our respiratory tract, nasal hairs acting as a coarse filter, and the cough reflex - all of which help expel unwanted airborne microbes and particles.

However, these protections may not work when particulates in the air are in such concentrations, or are so toxic, that our natural defences are not dequate enough to protect our respiratory system.

An array of exposures can cause respiratory health problems and irritate pre-existing conditions.

According to the Australian Bureau of Statistics1, about 14 per cent of all deaths in Australia are caused by lung diseases such as mesothelioma, asthma, lung cancer, asbestosis and pneumonia.

Some of these diseases are caused by personal choices including smoking, while others, such as asthma, can be a combination of hereditary and environmental conditions.

Air conditions in the workspace.

Dust, mists, smoke and sprays are just some of the substances that can make you sick or even lead to death if exposed to significant airborne concentrations while working for prolonged periods in industrial locations.

A range of industries such as coal mining, heavy manufacturing and agriculture are known to create conditions that can expose workers to various materials that adversely affect their health.

One such disease that afflicts workers is COPD, which is the narrowing of the airways. According to the book Clinical Management of Chronic Obstructive Pulmonary Disease2(second edition) published by CRC Press, there is a growing body of evidence that show environmental factors are causing the disease.

This can include occupational exposure to fine particulates, grains, heavy metals like cadmium or chromium, coal, silica and other mineral dusts and welding fumes, which increase the risk of the disease. The same report stated that up to 19 percent of cases of the disease in the working population in the US aged between 30-75 were caused by occupational exposures attributed to the aforementioned factors.

Not only should employees be protected from airborne contaminants for ethical reasons, it is in the employer’s interest that workers have the correct personal protective equipment (PPE). If a worker gets sick or contracts a lung disease from exposures due to the lack of suitable PPE, it can open up the employer to a range of legal and economic implications. This can include anything from an intrusive investigation by workplace health and safety regulators through to an employee missing work for an extended period of time.

This is why a respirator can be an essential part of PPE and necessary when people are working in places where particles are a hazard. Although not a standalone solution, a respirator correctly chosen and used can be a vital part of a number of workplace controls that help make sure health and safety laws are being adhered to by all parties.

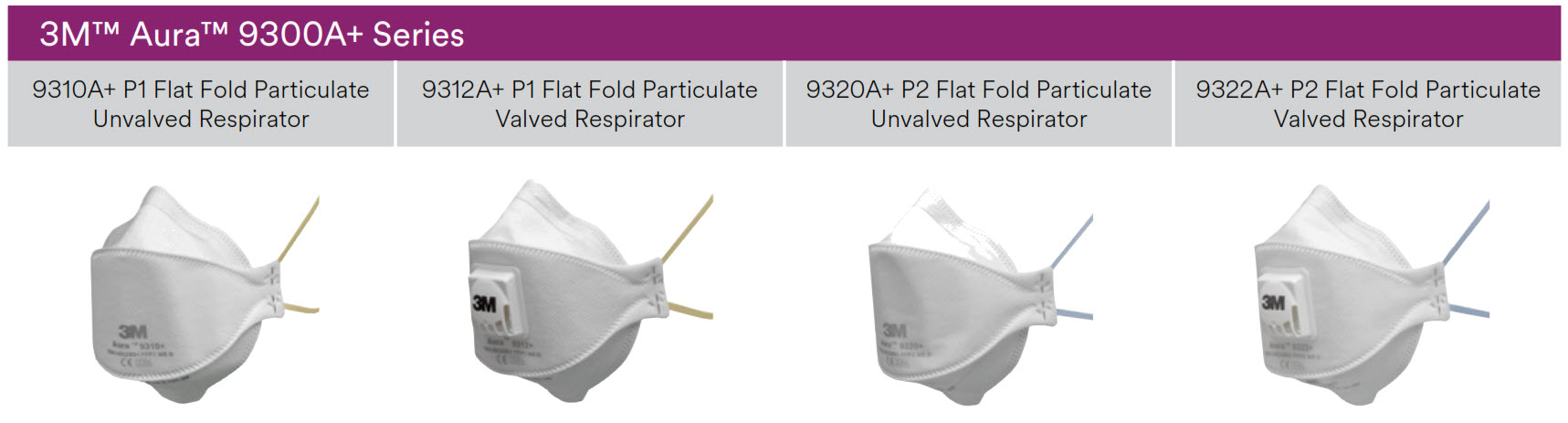

3M Aura 9300A+ series of disposable respirators.

3M’s Aura 9300A+ range of disposable respirators has been designed specifically for industries where occupational issues, such as exposure to dusts and other airborne particles that can intrude into a person’s airways, are a common, ongoing occurrence.

There are two types of 3M Aura 9300A+ respirators – valved and unvalved. The valved version includes an exhalation valve, which allows for quicker dispersal of the wearer’s hot, humid exhaled breath, which works better in an environment where workers exert more energy.

Key features.

Key features.

The fit - the 3M Aura 9300A+ series’ threepanel design means it can fit a wide range of face shapes and sizes. The sculptured soft nose panel allows it to fit comfortably on your nose without any annoying pressure on this sensitive area of the face. Like any tight fitting mask, Aura respirators are not suited for those with facial hair or stubble that interferes with the face seal of the product.

Breathing resistance - the electret particulate filter media in the advanced low-breathing resistance filter is said to reduce breathing resistance by up to 85 percent compared to other similar devices. Breathing resistance is that uncomfortable feeling where you feel it is difficult to pull air through the mask.

Removes heat build-up - the 3M Aura 9300A+ series products with an exhalation valve have enhanced performance to more easily remove heat and humid breath through the valve.

Embossed top panel - this helps control the flow of exhaled air through the top panel, helping to reduce the fogging of eyewear.

Fit testing kits.

A vital accessory to the 3M Aura 9300A+ range is the 3M FT-10 or FT-30 fit testing kit, which allows users to carry out a qualitative fit test. It is designed to check the face-to-respirator seal on any tight-fitting respirator fitted with a particulate filter. Users spray a bitter or sweet solution into the hood environment and perform a number of simple head movements. If the wearer tastes the spray while completing a series of exercises, then the fit is not acceptable and the product needs to be refitted or a different model selected.

3M’s Aura 9300A+ range is designed to be a cost-effective respiratory solution for hazardous working conditions where particulate exposure is

an issue.